In the world of automobiles, every turn of the wheel is a dance between power and control. As technology continues to push the boundaries of what's possible on the road, a captivating choreography known as torque vectoring takes center stage. Imagine a ballet of forces, a symphony of mechanics, and a harmony of algorithms—all working together to elevate the driving experience to new heights of excitement and safety.

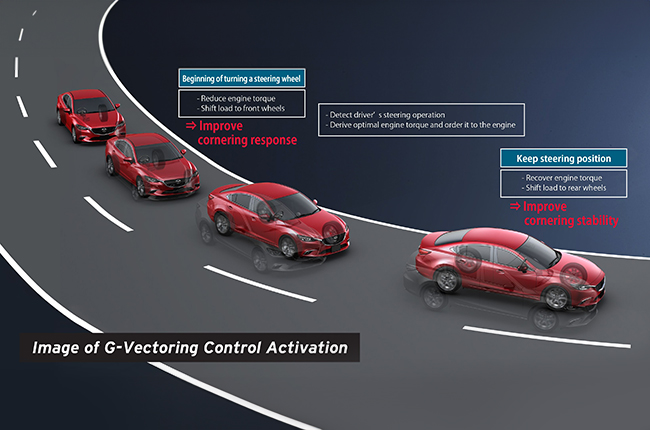

At this point in time, you might have read in a car brochure somewhere that torque vectoring is included in your vehicle. From the Mitsubishi Xpander Cross’ Active Yaw Control (AYC) to Mazda’s G-Vectoring Control, we are here to explain what torque vectoring really is and why it isn’t some type of marketing jargon.

Before we can truly grasp the magic of torque vectoring, we must first understand the essence of torque itself. In simple terms, torque refers to the twisting force an engine generates, typically measured in pound-feet (lb-ft) or Newton-meters (Nm). It is the rotational force that propels the wheels forward, allowing vehicles to overcome inertia and climb slopes with ease.

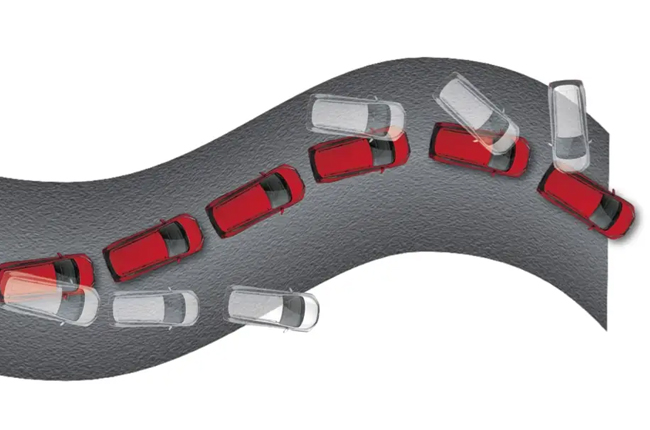

Traditionally, power was distributed equally to all wheels, offering a simplistic and somewhat limited approach to traction and handling. This approach often resulted in understeer or oversteer during cornering, where the car tends to drift wide or tuck in excessively. To overcome these challenges, automotive engineers devised an ingenious solution—torque vectoring.

Although the concept of torque vectoring had been simmering in the automotive industry for decades, especially with all-wheel drive (AWD) World Rally Championship (WRC) motorsport cars and homologation vehicles, its true potential came to fruition in recent years. The dawn of electronic stability control (ESC) and advancements in computer processing opened doors to a new era of vehicle dynamics.

Torque vectoring represents a departure from conventional differential systems, which passively distribute power based on resistance. Instead, it involves actively managing the torque to each wheel, precisely adjusting the amount of power delivered in real-time, depending on various factors such as steering input, wheel speed, and vehicle dynamics.

Torque vectoring employs various technologies and methodologies to manipulate the vehicle's movement masterfully. Among these, two of the most prevalent systems are brake-based torque vectoring and torque-vectoring differentials.

Brake-based torque vectoring involves selectively applying the brakes to individual wheels during cornering. By slowing down the inner wheel slightly, it creates a momentary imbalance, causing more torque to be transferred to the outer wheel. This process helps the vehicle turn more sharply, reducing understeer and enhancing overall stability. The electronic brain orchestrating this dance continuously monitors sensor inputs and adjusts the brake pressure seamlessly, ensuring a graceful performance on any road.

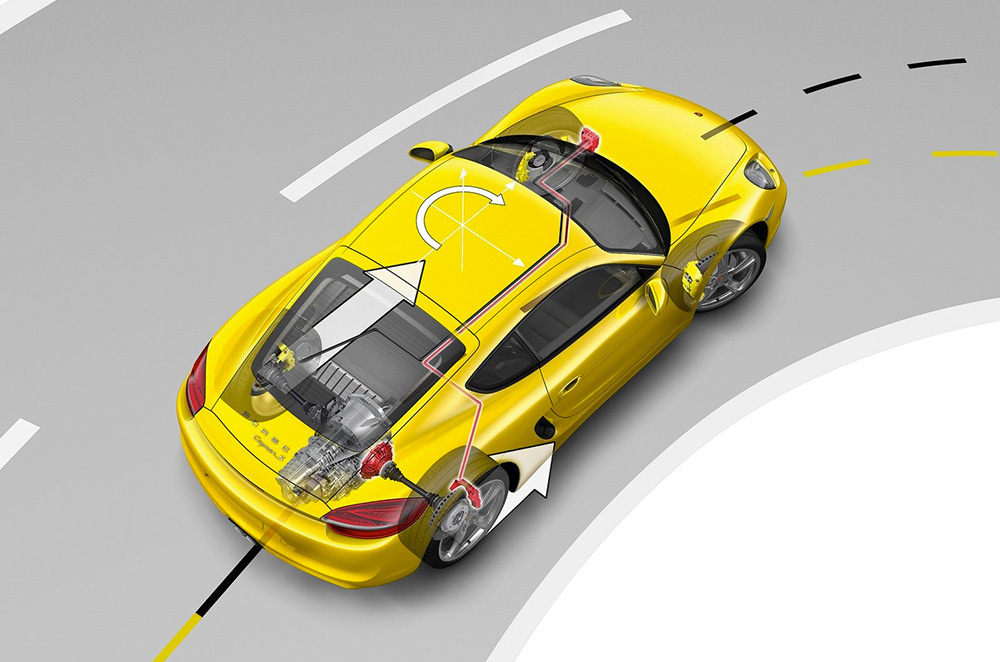

Taking a more mechanical route, torque-vectoring differentials use a set of gears or clutches to manage the distribution of torque between the left and right wheels. These differentials can be active or passive, with the active variants employing sophisticated electronic controls to optimize torque distribution actively.

At the heart of torque vectoring lies a symphony of algorithms and sensors that interpret the driver's intentions and the vehicle's dynamic state. From steering angle and wheel speed to yaw rate and lateral acceleration, an array of sensors feed data to the central electronic control unit (ECU). The ECU, armed with proprietary algorithms and machine learning capabilities, processes this data and orchestrates the optimal torque distribution strategy.

This intelligent manipulation of torque enhances not only the car's agility and cornering abilities but also its safety. By intelligently redistributing power, torque vectoring can mitigate the risk of oversteer or understeer, preventing potential loss of control in challenging driving conditions.

To explain this in a more laid-back manner, when taking a corner hard, the vehicle wants to drag you inside the corner more, hence reducing understeer, especially for front-wheel-drive (FWD) and all-wheel-drive cars (AWD).

The rise of torque vectoring has left an indelible mark on the driving experience, redefining the limits of performance and safety. In performance-oriented vehicles, torque vectoring allows drivers to carve corners with surgical precision, inducing a sense of connection and excitement previously reserved for racing circuits.

Beyond the thrill of spirited driving, torque vectoring has also had a profound impact on safety. By fine-tuning the power delivery to each wheel, the system can enhance stability and grip, especially in adverse weather conditions or emergency maneuvers. This technology has revolutionized the world of driving making them more than just a tool for high-speed rallying but also a means to elevate on-road confidence and control on the tarmac.

All in all, it’s great to see this technology trickle down to regular road cars, if it means added safety, and more importantly, added fun in the corners.

Latest Features

-

An all-electric future: The Porsche Macan Electric / Featured Article

Porsche’s Macan goes all-electric; it’s a new beast with an electrified heart, yet unmistakably Porsche in performance and spirit.

-

Which Kia should I buy? / Featured Article

We’re here to help you decide which Kia vehicle is best for you, whether it’s a sedan, crossover, or minivan.

-

Why Lynk & Co is a good option for luxury car buyers / Featured Article

Lynk & Co offers premium value for those exploring the luxury market.

Popular Articles

-

Electric Vehicles in the Philippines for under P1 million

Jerome Tresvalles · Aug 19, 2025

-

Top 3 Cars For Every Lifestyle—What Cars Are Right For You? | Behind a Desk

Caco Tirona · Apr 24, 2024

-

5 Tips to Maximize Fuel Efficiency

Jerome Tresvalles · Sep 09, 2024

-

Five driving habits that are draining your fuel tank

Jerome Tresvalles · Jun 24, 2025

-

Can engine braking harm your engine?

Jerome Tresvalles · Sep 11, 2025

-

Do electric cars even need maintenance?

Jerome Tresvalles · Oct 23, 2024

-

Best vehicles for an active outdoor lifestyle

Shaynah Miranda · Jul 25, 2024

-

How to drive different types of vehicle transmissions

May 23, 2024

-

5 easy ways to keep your car interior clean

Allysa Mae Zulueta · Nov 15, 2021

-

How to survive Metro Manila traffic

Earl Lee · Aug 16, 2022